Laser Cutting Service Providers in Pune

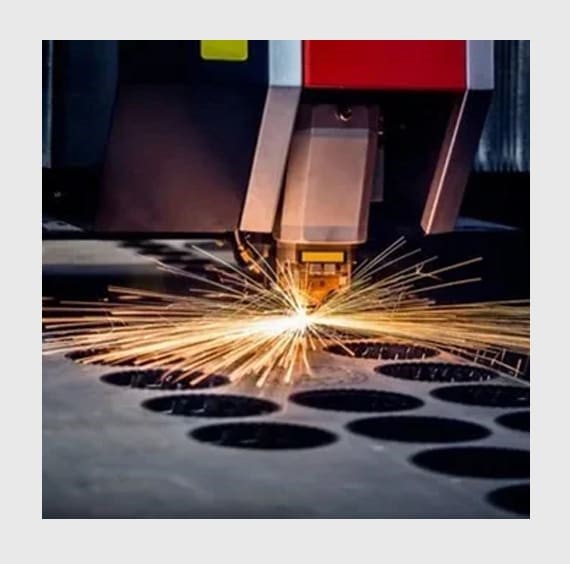

Divya Metal a top Laser cutting services in Pune. We provide high-precision cutting solutions across the different industries. This cutting-edge technology employs a focused and high-intensity laser beam for cutting, engraving, and etching materials like metals, plastics, wood, and composites to precision.

Within the manufacturing realm, these laser cutting services are creating complex designs in the automotive, aerospace, electronics, medical, construction, and advertising industries, thus, permitting the efficient use of raw materials without wastage.

It can cut virtually all manners of materials and thicknesses, rendering it exceptionally useful for industries that call for detailed custom fabrications. With speed and automation further enhancing productivity, laser cutting would thus be able to minimize lead time and operational costs.

Laser Cutting Solutions in Pune

The no-contact nature of processing causes no mechanical stress or tool wear, creating clean, burr-free edges. The real strength of laser cutting is on repeatability and accuracy in mass production applications, while raw material cost savings for large volume runs increase profitability. Advanced integration of CNC with CAD software maximizes the flawless execution of complex designs. These applications include automotive parts, aerospace components, medical instruments, architectural constructs, custom signages, etc. For far superior success, laser cutting service providers in Pune that are in the pursuit of cost-effective, quality cutting solutions.

Types of Laser Cutting Services in Pune:

CNC Laser Cutting Services are widely used in various industries due to their precision, speed, and versatility. Here are the types of Laser Cutting Solutions in Pune:

- CO₂ Laser Cutting: Uses a gas laser with a CO₂ mixture for a high-energy beam. Best for non-metal materials like wood, acrylics, plastics, and textiles. Used in signage, engraving, and packaging. Not suitable for highly reflective metals.

- Fiber Laser Cutting: Uses a fiber-optic system to generate and amplify the laser beam. Most effective for cutting metals like stainless steel, brass, and aluminum. Faster and more energy-efficient than CO₂ lasers for metal processing. Minimizes maintenance and offers high precision.

- Nd:YAG Laser Cutting: Uses a solid-state laser with a Neodymium-doped Yttrium Aluminum Garnet crystal. High accuracy for cutting both metals and some non-metals. High power density, suitable for deep cutting and welding.

- Plasma-Assisted Laser Cutting: Combines laser cutting with a plasma torch for cutting thick materials. Used in heavy-duty applications like shipbuilding and construction. More effective than conventional plasma cutting for metals.

- Micro Laser Cutting: Uses ultra-fine laser beams to cut delicate structures and small parts. Popular in manufacturing semiconductors, medical devices, and electronics. Effective for cutting tiny and sophisticated structures with high precision.

Feature and Benefit of Laser Cutting Solutions in Pune:

These are the following features and benefits which are applied for Laser Cutting Service Providers in Pune:

- Very High Precision and Accuracy: A laser cuts very fine, accurate, and high-quality results with a relatively concentrated beam. The cut is very straight with little errors. A sufficiently sharp-tolerance intricate design will be possible. It is ideal for industries requiring intricate designs, like aerospace and electronics.

- Versatility of Material: Laser cutting processes metals, plastics, wood, glass, and derivatives without changing the thickness or properties and without changing the tool frequently. For easy use, it can be applied to different industries, such as construction, medical, and automotive.

- Real Efficiency & Speed: Laser cutting is by far more efficient than the normal traditional methods of cutting in terms of saving time in the production process. The whole procedure is contactless, thus saving on tool sharpening or replacement.

- Exceptionally Minimal Waste of Materials: Not only does it assure precise cutting, but ensures the most optimized usages of materials minimizing scrap and waste. A narrow kerf is synonymous with less removal of material and hence maximized efficiency.

- Automation and Consistency: Laser cutting machines can be connected with CNC systems for automatic and repeatability process. This increases the productivity of mass manufacturing industries such as electronics, automobiles, and fabricators.

Applications of Laser Cutting Solution Providers in Pune:

These are the following application which is effective and sustainable for laser cutting services in Pune:

- Industry and Manufacturing: Laser cutting is used to precisely cut sheets, pipes, and components from metals for various sectors like automotive, aerospace, and machinery, minimizing material waste and production time.

- Electronics and Electrical: Laser cutting fabricates circuit boards, casings, and micro-components in electronic devices, producing fine, intricate cuts with minimal material damage.

- Signage and Advertising: This technology creates signs, including 3D letters and complex logos, from acrylic, wood, and metal, enabling customized production with smooth edges and fine detail. Laser engraving is also used for branding and promotional gifts.

- Jewellery and Fashion: Laser cutting creates intricate designs on metals, leather, and synthetic fabrics, offering capabilities beyond conventional methods.

- Architectural and Interior Design: Laser cutting forms customized decorative panels, artistic engravings, and furniture parts, including metal screens, wooden inlays, and glass etching, allowing architects and designers to create complex designs.

Divya Metal is best Laser Cutting Services in Pune, and Service Providers in Pune. Laser cutting services are the way to go when it comes to precision, efficiency, and adaptability. As leading Laser Cutting Solution Providers in Pune. CNC Laser guarantees, cost-effectiveness and quality output through maximum CNC integration with minimal material waste and high-speed automation. Different kinds, such as CO₂, fiber laser, Nd:YAG, plasma-assisted, and micro laser cutting, have specifications needed for specific materials and thicknesses. It is used in applications ranging from industrial manufacturing to high-fashion, handmade jewellery, custom signage. Contact us today to get the best deals for Laser cutting solution.