Leading Sheet Metal Bending Services in Pune for All Industries

Divya Metal a top leading sheet metal bending services in Pune. Metal sheet bending Services are the single stage of metal fabrication, which converts flat sheets into accurate and durable parts utilized in many industries. The technique involves exerting pressure on metal sheets to reach determined angles, orientations without spoiling the strength of the material.

Customized Sheet Metal Bending Solutions in Pune for Your Business Needs

This Sheet Metal Solutions has started to employ the most effective CNC press brakes and walking beam automatic bending machines. Sheet metal bending is, therefore, important in the automotive, aerospace, construction, and electronics industries for brackets, enclosures, panels, and custom parts.

Types of Sheet Metal Bending Services:

For suitable and convenient use in services these is beneficial following are the types of services provided by sheet metal bending service providers in Pune.

- Air Bending: In the method of air bending, a metallic sheet is pressed into a die using a punch, without fully reaching the interior surface of the die as shown in the illustration. This allows convenient adjustment of angle with a minimal applied force.

- Bottoming Coining: Bottoming, on the other hand, refers to the complete penetration of sheet metal into the die cavity such that there is no room for adjustment thereafter in relation to the angle defined by the bend. Because of that, bottoming requires greater tonnage and is specific, but it also yields tighter tolerances needed in specific applications.

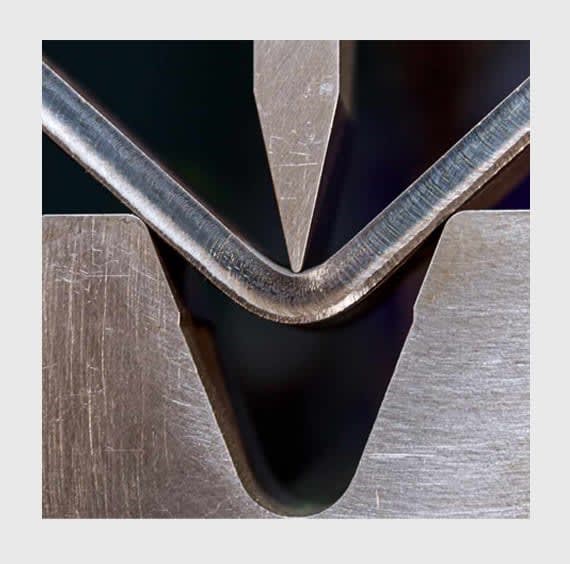

- V-Bending: V-bending is a mechanical forming process using a punch and V-shaped die to create a specific angle of bend. It represents the most widely used format in forming and able to be applied on virtually any type of material or thickness for sheet metal solution providers.

- U-Bending: In a U-bend, the metal is pressed between punch and a U-die to result in a U-shape. It typically finds use in construction as well as automotive applications. This process features some pretty strong and consistent bends required for higher strength applications.

- Roll Bending: Roll bending gets its name from the fact that the process employs three rollers in order to gradually roll the piece of metal in order to shape it into either curved or cylindrical form. It is significant for making tubes and pipes and large-radius bends.

Features and Benefits of Sheet metal bending services:

They used for determine effects and they have different key benefits which is useful and following are the benefits of given by Sheet metal bending services Pune.

- Strengthened Durability & Strength: Bending reduces the requirement of additional joints or welds, eliminating weak spots in metalwork. Overall, it increases duration and durability, making components more resistant to budding and deformation.

- Fine Precision & Tolerance: Advanced CNC bending machines guarantee accurate and equal bends. This facility decreases human error that might affect production due to excessive measurement, crucial in industries like aerospace and automotive manufacturing.

- Cost Consumption of Production: Bending reduces production costs by minimizing the need for extra welding, fasteners, and material wastage. The efficiency of this process eventually reduces labor time and provides better value for large production runs.

- Design Flexibility: Manufacturers prefer sheet metal bending to create sophisticated shapes or custom designs without using expensive molds or tools. This enables the production of lightweight but strong parts for specific applications.

- Improved Aesthetics plus Work and Performance: Bending creates elongated, beautiful, seamless curves, making end products more attractive. It also ensures better fitment and reduces sharp points, which can pose safety concerns.

Applications of Sheet metal bending services:

Sheet metal bending services has been used in industries that demand very high strength and consistency. These are the applications of sheet metal bending service providers in Pune:

- Automotive: Used for designing body panels and chassis structures, ensuring precision and durability for vehicle frames and enclosures. Minimizes waste and maximizes productivity.

- Aerospace: Strengthens lightweight components for aircraft structures, including wing sections, fuselage panels, and brackets. High precision ensures compliance with safety standards.

- Construction & Architecture: Used for metal frameworks, roofing sheets, and exterior decorations, enhancing aesthetics, durability, and structural and interior design possibilities for modern buildings.

- Electrical Enclosures and Cabinets: Creates protective enclosures for electrical panels and devices, safeguarding components from external damage and offering flexibility in sizes, designs, and material selection.

- Furniture and Home Appliances: Used to make steel tables, racks, and kitchen appliances, providing structural strength without compromising sleek aesthetics. Enables low-cost mass production for domestic products.

Divya Metal, a top sheet metal bending services in Pune, services relying on sheet bending services is based on precision, strength, and economical production of different components in metal. The unique properties of CNC press brake bending and automated operations increase the lifespan of the metal material while minimizing wastage. Bending processes like air bending, bottoming, U bending, V bending, and roll bending are advantageous for different applications and high tolerance applications. Get in touch with us today! to get the best deals for sheet metal solution providers in Pune.