Expert MS Laser Cutting Services in Pune – Divya Metal

Divya Metal is a top MS Laser cutting services in Pune. We provide services suitable for the precision cutting requirements of various industries. Clean and precise cutting of complex designs on mild steel sheets and components is provided by advanced laser technology. The automotive, construction, manufacturing, and fabrication industries, to name a few, increasingly appreciate MS laser cutting due to its efficiency, cost-effectiveness, and unparalleled ability to handle intricate designs. These productivity benefits, along with lead time reduction and increased quality of products, accrue to firms that value reliable and high-quality cutting processes.

Reliable MS Laser Cutting Services in Pune for Your Metal Needs

MS laser cutting services are favoured for generating almost no wastages of materials and providing much superior edge quality than other traditional works. They quickly finish projects that other methods would take forever to complete. Keeping this in mind, these projects are being executed with extreme precision over various thickness levels of mild steel.

Types of Laser Cutting Services

Laser cutting is widely used across various industries due to its precision, speed, and ability to cut complex shapes with minimal material wastage. Here are the following types of MS Laser cutting Services in Pune

- CO₂ Laser Cutting: Uses a CO₂ gas laser for high-precision cutting of MS sheets with smooth edges, suitable for low to medium thickness (up to ~10mm) cuts. Ideal for fine cuts with small dimensions, widely used in the automotive, sign making, and metal sheet fabrication industries.

- Fiber Laser Cutting: Employs fiber optic technology for fast and efficient cutting of MS sheets up to 25mm thick. Offers higher energy efficiency and lower maintenance costs compared to CO₂ lasers.

- Plasma-Assisted Laser Cutting: Combines laser and plasma cutting for deep cuts in thicker MS plates (above 20mm). Delivers high-speed cutting with reduced slag and heat distortion.

- Pulsed Laser Cutting: Uses short, intense laser energy pulses to cut MS with minimal heat-affected zones. Best for precision cutting of small, complex parts in electronics, medical devices, and micro-fabrication applications.

- Hybrid Laser Cutting: Combines laser cutting with mechanical or water jet cutting for highly precise applications. Reduces thermal distortion while maintaining excellent cut quality, used in aerospace, defense, and specialty engineering industries.

Features and Benefits of MS laser cutting services:

These are applicable in different point of view and for different designs benefits by MS Laser cutting service providers in Pune as follows:

- High Precision and Accuracy: Laser cutting delivers high precision and accuracy, ideal for complex geometries and intricate designs. It ensures accurate and precise cuts, meeting strict tolerance requirements in various industries.

- Fast Speed and Efficient Cutting: Fiber and CO₂ lasers offer high cutting speeds, up to 50m/min, significantly reducing production lead times compared to traditional MS cutting methods, enhancing overall productivity.

- Minimal Material Waste: The narrow laser beam optimizes raw material usage, minimizing scrap and waste. This reduces costs and promotes sustainable manufacturing practices, aligning with lean manufacturing and resource efficiency.

- Thick Material and Flexible Designs: Laser cutting can handle a wide range of material thicknesses, from thin sheets (0.5mm) to thick plates (50mm), enabling the creation of customized designs, holes, and complex structures for automotive, aerospace, construction, and fabrication industries.

- Smooth Edges Without Burr: Laser cutting produces clean, high-quality cuts with smooth edges, eliminating the need for post-processing like grinding and deburring. This saves time and improves the final product's appearance and functionality.

Applications of MS laser cutting services:

These are the following application used for different industries and in different frameworks provided by MS Laser cutting services in Pune and MS Laser cutting service providers in Pune:

- Automotive Industries: MS laser cutting is used to manufacture precision components like vehicle chassis parts, brackets, and exhaust systems, ensuring high accuracy and consistency.

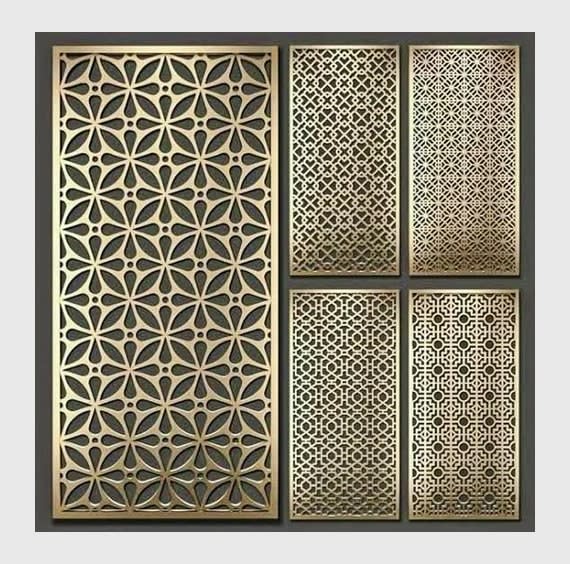

- Construction and Infrastructure: Laser-cut MS plates are used in structural frameworks, staircases, handrails, and facade panels, enabling intricate detailing suitable for modern architecture and ornamentation.

- Industrial Machinery and Equipment: Laser cutting is essential for manufacturing machine parts, casings, and enclosures used in industrial equipment, producing custom parts with minimal errors and ensuring compatibility in machine assemblies.

- Advertising and Sign Making: This modern technique creates customized metal signs, logos, and artistic engravings with steel, providing weatherproof and professional branding solutions.

- Furniture and Interior Design: Laser cutting is used to make designer-frame furniture, decorative metal panels, and modern room partitions, allowing for precise artistic patterns that enhance home and office interiors.

Divya Metal a top MS laser cutting services in Pune. MS laser cutting services provide high-precision cutting, cost-effective and affordable for several industries. Laser cutting technologies that include CO₂, fiber, pulsi, and hybrid, allow cutting with almost no wastage, razor-sharp edges, and with many intricate designs. Apart from being cut for different thickness levels of mild steel accurately and fairly quickly, this technology is a great solution for modern manufacturing needs. Overall, the MS laser cutting improves productivity, decreases the lead time, and gives a very premium finish component for various applications. Reach out now and experience seamless service to get the best deals for MS laser cutting solution providers in Pune.